Kneader Compounding Extruder Line Sale

Kneader reactor technology has long been used for what is known as “Process Intensification”, where multiple processing steps are performed in the same unit. Such units are characterized by high yield per performance volume and also have the flexibility to produce different grades and/or products.

Main APPlications

◆ TPU/TPE/TPO/TPR ◆ High Density Color Masterbatch

◆ High Filled Filler ◆ Other Customized Field

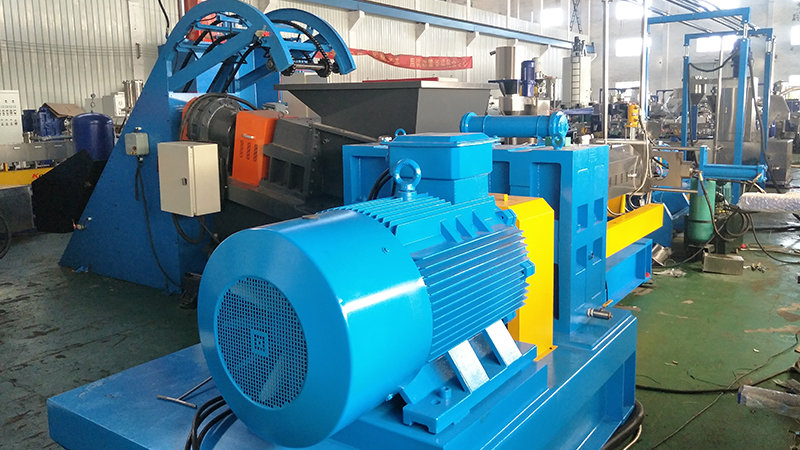

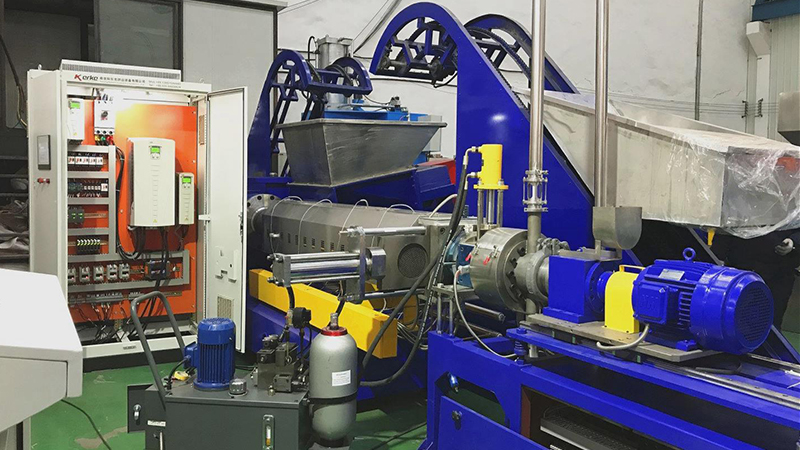

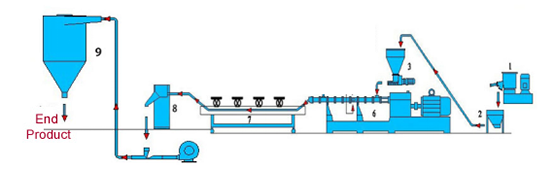

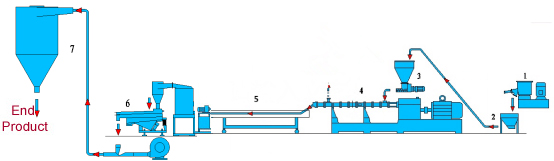

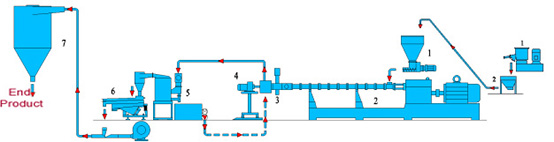

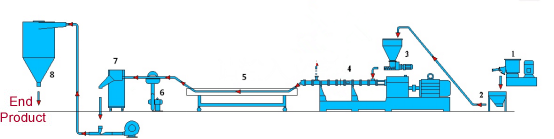

Kneader + Extruder For Plastic Application

Kneader reactor technology has long been used for what is known as “Process Intensification”, where multiple processing steps are performed in the same unit. Such units are characterized by high yield per performance volume and also have the flexibility to produce different grades and/or products. We only focus on plastic application especially for thermoplastic application like TPU/TPE/TPO and high filled masterbatch like Caco3 filler (Caco3 over 85%), carbon black masterbatch (carbon black over 40%). We can provide output from 100kg/hour to 1200kg/hour

Advantages of Our Kneader Compounding Extruder Line

- Excellent mixing and kneading performance during wet, pasty and viscous phases

- Compact design maximizing process yield per performance volume and minimizing space requirement

- Narrow residence-time distribution for plug flow operation

- Maximum self-cleaning

- Large heat-exchange surface areas yielding highest possible surface-to-volume ratio

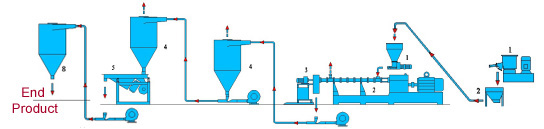

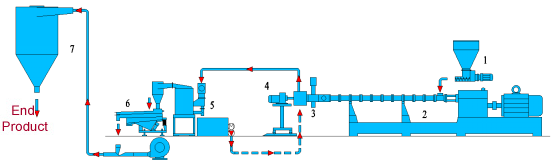

There are 6 different cutting types for different application

According to your raw materials, We can customize the best solution for your business.

Water-cooling Strands Cutting Type

Air-cooling Hot-face cutting type

Water-ring Hot-face cutting type

Air-cooling strands cutting type

Water-flowing Cutting Type

UnderWater Cutting Type

Wons Customers By superior Quality

- KERKE has over 11 years experience in compounding extruder;

- We produce core parts like screw elements, barrels by ourself;

- Our team are professional to ensure quality and service;

- Our extruders have been sold more than 60 countries.

Our Extruder Is Enough For You

- You should know that, Europe extruder quality is better than China, because of the steel level. If you can pay 5 times price, you can buy Europe brand;

- If your application is normal filler masterbatch, color masterbatch, engineering plastics, PET f lakes recycling etc. China extruder is enough for you. Will be no any problem;

- Kerke just provides high cost-effective extruder to you, not the highest, neither the lowest, but the more suitable for your business.

We Supply Good Extruder With Reasonable Price

- Extruder Price determines your end product production costper ton, Good price, better competitive advantage;

- Kerke extruder price can make you earn back equipmentinvestment in 2-3 months;

- We do not sell the cheapest extruder, just good qualityextruder at good price;

- You should care about the cheap extruder supplier, there areonly 2 reasons: 1. their quality is so bad with that so cheapprice; 2. That supplier does not have profit at so cheap price, can you imagine a supplier sell extruder with no profit? Howcan they promise the quality and service? I believe ourcustomers are smart, can not be cheated.

Service - Back Support For Your Business

- When you bought good extruder at good price, after-sale servicemeans more for your business success;

- Kerke can provide 7x24 hours a week after-sale service, wepromise you get our support in 2 hours;

- We can post you the spare parts you need in 24 hours;

- Kerke support team located more than 5 countries, China, Iran, Turkey, Indonesia, Pakistan, Mexico etc;

- Kerke service even including market analysis, project feasibilityanalysis, formula guide, competitor investigation etc;

- Your business success need a good partner - Kerke.