LFT-G Extrusion Pelletizing Machine

Factory-direct Sales, Customized Solutions for Your Products

LFT-G Extrusion Production Line

LFT-G (Long Fiber Thermoplastic-Glass) technology involves fully impregnating continuous fibers (glass, carbon, basalt, etc.) with molten thermoplastic resin in a precision impregnation mold. The composite is then extruded through a shaping die head, cooled, and cut into pellets (6–25mm length), ensuring retained fiber length matches pellet size for superior mechanical properties.

※ Compatible Thermoplastics: PP, PA6, PA12, PA66, PC, PPA, PET, PBT, PLA, TPU, PPS, PEEK, and more;

※ Reinforcing Fibers: Glass/carbon/basalt/polymer fibers;

※ Output (kg/h): 50–1000; Fiber Count: 6-72; Fiber Content 30%-60% (customizable); Pellet Length: 6–25 mm (adjustable)

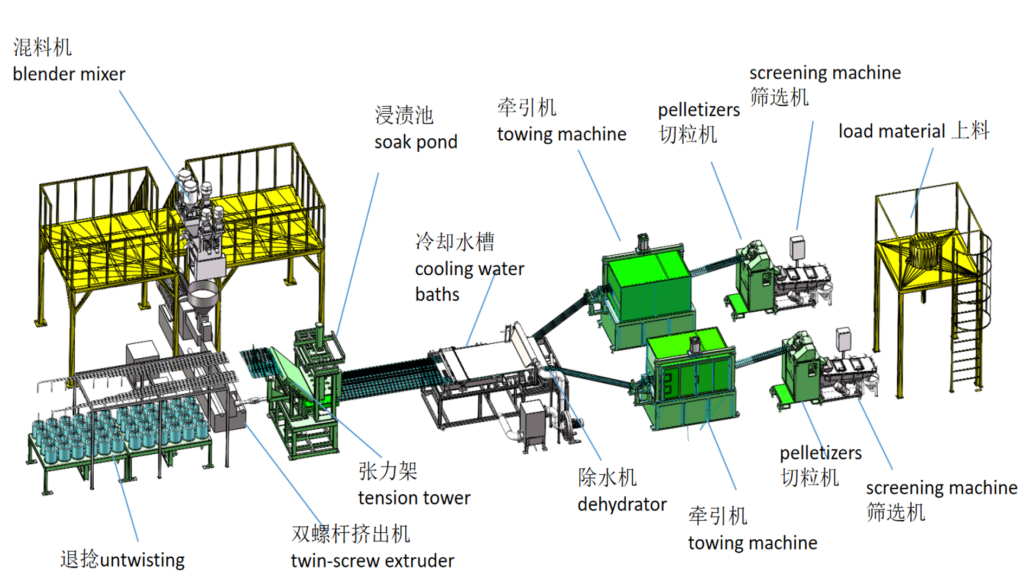

Long Fiber Reinforced Thermoplastic Extrusion (LFT-G) Production Line

LFT-G (Long Fiber Thermoplastic-Glass) technology involves fully impregnating continuous fibers (glass, carbon, basalt, etc.) with molten thermoplastic resin in a precision impregnation mold. The composite is then extruded through a shaping die head, cooled, and cut into pellets (6–25mm length), ensuring retained fiber length matches pellet size for superior mechanical properties.

End-to-End Solutions: From material feeding to pellet packaging.

Customization: Adapt configurations for specific resins, fibers, or industries.

Global Support: 60+ countries served with lifetime technical assistance.

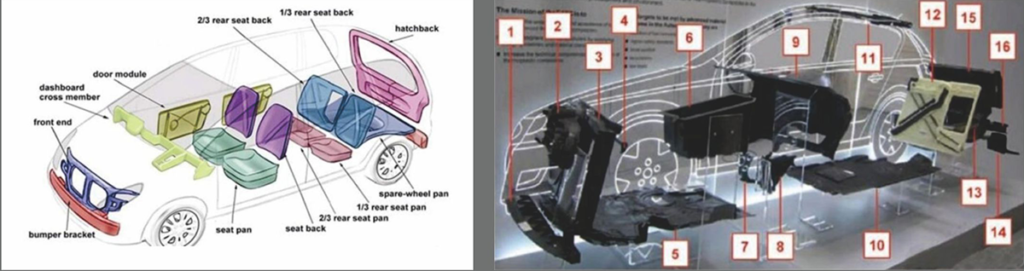

Industries Served

🚗 Automotive: Lightweight battery housings, structural components.

🛩 Aerospace: High-strength composite parts.

📱 Consumer Electronics: Durable casings, precision components.

🏥 Medical: Sterile, high-performance equipment.

🏋 Sports & Furniture: Impact-resistant, lightweight designs.

Key Features of our LFT-G Production Line

- High-Quality Impregnation: Uniform resin distribution with minimal fiber damage and controllable fiber content (30%–60%).

- Modular Design: Components include a twin-screw extruder, fiber pre-dispersion, melt impregnation, cooling, pelletizing, and automated control systems.

- High Efficiency: Achieves 20% lower energy consumption and 35% higher output vs. traditional methods.

- Precision Control: Real-time monitoring of temperature, fiber speed (5–60 m/min), and pellet length ensures consistent quality.

- 7×24 Hours High performance and good after-sale service

Main Parts of the Production Line

Technical Specifications for Hot-selling Models

| GF Specific | GF Content | Speed (m/min) | Capacity (kg/h) | Per Roll (17kg) (m) | COT(min) | Utilization Rate |

|---|---|---|---|---|---|---|

| 2400TEX | 60% | 50 | 576.00 | 7291 | 145.83 | 89.29% |

| 2400TEX | 60% | 40 | 460.80 | 7291 | 182.29 | 91.24% |

| 2400TEX | 50% | 60 | 829.44 | 7291 | 121.53 | 87.41% |

| 2400TEX | 50% | 50 | 691.20 | 7291 | 145.83 | 89.29% |

| 2400TEX | 40% | 60 | 1036.80 | 7291 | 121.53 | 87.41% |

| 2400TEX | 40% | 50 | 864.00 | 7291 | 145.83 | 89.29% |

| 2400TEX | 40% | 40 | 691.20 | 7291 | 182.29 | 91.24% |

| 2400TEX | 40% | 30 | 518.40 | 7291 | 243.06 | 93.28% |

| 2400TEX | 40% | 20 | 345.60 | 7291 | 364.58 | 95.42% |

| 2400TEX | 30% | 50 | 1152.00 | 7291 | 145.83 | 91.24% |

| 2400TEX | 30% | 40 | 921.60 | 7291 | 182.29 | 93.28% |

| 2400TEX | 30% | 30 | 691.20 | 7291 | 243.06 | 95.42% |

| 2400TEX | 30% | 20 | 460.80 | 7291 | 364.58 | 95.42% |

| 2400TEX | 20% | 50 | 1728.00 | 7291 | 145.83 | 91.24% |

| 2400TEX | 20% | 40 | 1382.40 | 7291 | 182.29 | 93.28% |

| 2400TEX | 20% | 30 | 1036.80 | 7291 | 243.06 | 95.42% |

| 2400TEX | 20% | 20 | 691.20 | 7291 | 364.58 | 95.42% |

Technical Specifications for Hot-selling Models

| GF Specific | GF Content | Speed (m/min) | Capacity (kg/h) | Per Roll (17kg) (m) | COT(min) | Utilization Rate |

|---|---|---|---|---|---|---|

| 2400TEX | 60% | 50 | 576.00 | 7291 | 145.83 | 89.29% |

| 2400TEX | 60% | 40 | 460.80 | 7291 | 182.29 | 91.24% |

| 2400TEX | 50% | 60 | 829.44 | 7291 | 121.53 | 87.41% |

| 2400TEX | 50% | 50 | 691.20 | 7291 | 145.83 | 89.29% |

| 2400TEX | 40% | 60 | 1036.80 | 7291 | 121.53 | 87.41% |

| 2400TEX | 40% | 50 | 864.00 | 7291 | 145.83 | 89.29% |

| 2400TEX | 40% | 40 | 691.20 | 7291 | 182.29 | 91.24% |

| 2400TEX | 40% | 30 | 518.40 | 7291 | 243.06 | 93.28% |

| 2400TEX | 40% | 20 | 345.60 | 7291 | 364.58 | 95.42% |

| 2400TEX | 30% | 50 | 1152.00 | 7291 | 145.83 | 91.24% |

| 2400TEX | 30% | 40 | 921.60 | 7291 | 182.29 | 93.28% |

| 2400TEX | 30% | 30 | 691.20 | 7291 | 243.06 | 95.42% |

| 2400TEX | 30% | 20 | 460.80 | 7291 | 364.58 | 95.42% |

| 2400TEX | 20% | 50 | 1728.00 | 7291 | 145.83 | 91.24% |

| 2400TEX | 20% | 40 | 1382.40 | 7291 | 182.29 | 93.28% |

| 2400TEX | 20% | 30 | 1036.80 | 7291 | 243.06 | 95.42% |

| 2400TEX | 20% | 20 | 691.20 | 7291 | 364.58 | 95.42% |

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.